CTC Upgrade 01

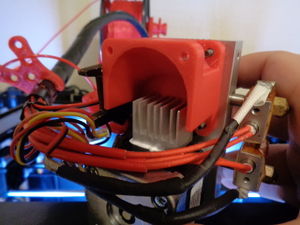

One of the problems I encountered with the CTC Bizer was the poor quality of the stepper motors. The extruder steppers would wear out quickly and be unable to produce the torque to push the filament through the nozzle (despite the nozzle being squeaky clean and setting the heat higher). I replaced the extruder stepper with a larger one. To keep the carriage light weight and keep the motor cool, I replaced the other stepper with a custom cowling, fan, and heat sink.

The cowling has NEMA 17 form factor and fits a 40mm fan on the back. You can then glue a heat sink to the side of the stepper motor (with thermal glue). You might want to file down the edge of the heat sink if it comes in contact with wires.

I've been using this for several months, and this modification has dramatically improved the reliability of the extruder.

Files

- CTCStepperSideFan.zip size: 1.0MB Download File